Sound Protection

SDS-Silencer

Type

SDS 3 – 30;

Diameter: 300 to 3000mm

Design / Application

Circular silencer to minimize noise emissions. Can be combined several times. Designed as a steel inline silencer with connecting flange on both sides and composite lugs.

Mining version with internal replaceable silencing elements, antistatic. Size adapted to underground material transport

Insertion Damping

8 – 15 dB

Coating

Primer with top coat, alkyd resin Silac, total layer thickness min. 180μm,

Standard colour: Pure white (RAL9010)

Options

Design as short version Type: SDSk with adapted lengths for narrow shaft transport

SDM-Silencer Modular

Type

SDM 3 – 25;

Diameter: 300 to 2500mm

Design / Application

Circular silencer to minimize noise emissions. Can be combined several times. Designed as inline silencer made of steel, connecting flange on both sides and composite lugs.

- Circular silencer to minimize noise emissions. Can be combined several times. Designed as inline silencer made of steel, connecting flange on both sides and composite lugs.

- Available in module lengths of 0.5m; 1m and 2m

Insertion Damping

8 – 15 dB

Coating

Primer with top coat, alkyd resin Silac, total layer thickness min. 180μm,

Standard colour: Pure white (RAL9010)

Options

Split design

SDSi-Silencer

(rigid with inner core)

Type

SDSI 7 – 30;

Diameter: 300 to 3000mm

Design / Application

Circular silencer to minimize noise emissions. Can be combined several times. Designed as a steel circular silencer with additional inner core for increased insertion damping, connecting flange on both sides and composite lugs. Mining version with internal replaceable silencer elements, antistatic. Size adapted to underground material transport.

Insertion Damping

10 – 20 dB

Coating

Primer with top coat, alkyd resin Silac, total layer thickness min. 180μm,

Standard colour: Pure white (RAL9010)

Options

Design as short version Type: SDSIk with adapted lengths for narrow shaft transport

NS-Silencer Noise Shield

Type

NS 14 – 24;

Diameter: 1400 to 2400mm

Design / Application

Duct silencers for minimizing noise emissions in special design. Three-part special module with increased insertion damping values in the low-frequency range. Differentiated as suction-side and pressure-side design.

Insertion Damping

15 – 22 dB

Coating

Primer with top coat, alkyd resin Silac, total layer thickness min. 180μm,

Standard colour: Pure white (RAL9010)

Options

Different length version of the intermediate module to adjust the total insertion damping

KSD - Baffle - Silencer

Type

KSD

Size depending on application

Design / Application

Fixed, specified sound insulation. In baffle design as absorption baffle. Square steel frame. Baffles made of perforated plate with inner cover and backed glass fleece as trickle protection. Absorption material: mineral wool (non-combustible according to DIN 4102)

Silencer directly connected or as peripheral unit in the track. For increased insertion damping above the attenuation limit of circular silencers.

Insertion Damping

According to the design

(Recommended for requirements > 25dB)

Coating

galvanized or painted according to application

Options

Combined mobile design in container / split design

(see also silencer type CS)

SH - Acoustic Hood

Type

SH 3 -14;

For fan sizes 300mm to 1400mm

Design / Application

Acoustic enclosure as complete housing of the fan and adjacent flow components. Solid specific sound insulation in sandwich construction with galvanized sheet metal. Multi-part design depending on the area of application.

Insertion Damping

to ~25 dB

Coating

galvanized

Options

Special design with cut-outs

LUM Silencer - Fan shroud

Type

LUM 3 – 18

Diameter: 300 to 1800mm

Design / Application

Flexible sheathing made of antistatic ducting materials, filled with specific mineral wool insulation, one- or two-part. For direct enclosure of the fan housing.

Insertion Damping

3 – 5 dB

Coating

Air duct material coating

Options

Special design with cut-outs; steel jacket design,

Antistatic

PSD Silencer - Impact silencer

Type

PSD 3 – 18

For fan sizes 300mm to 1800mm

Design / Application

Noise protection screen as a fixed insulating screen made of sheet steel with mineral wool insulation. On the intake side on spacer bolts to reduce the axially acting sound emissions.

Insertion Damping

10 – 15 dB

Coating

Primer with top coat, alkyd resin Silac, total layer thickness min. 180μm,

Standard colour: Pure white (RAL9010)

Optionen

Adaptation special compensators, special flange,

split execution

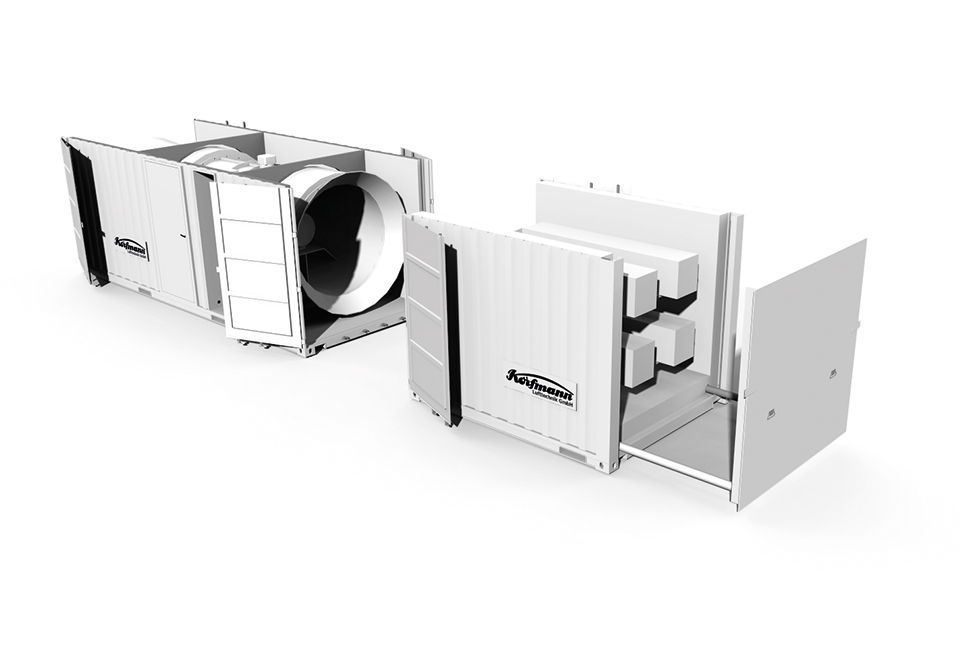

CS - Container - Silencer

Type

CS 10 – CS 40

Design / Application

Fully lined container. Sound enclosure by insulating material under galvanized perforated plate plating. As complete enclosure of axial fans, insertion loss after execution. With integrated baffle silencer depending on requirements. Versions from the baffle silencer in a 10″ container to the 40″ integral container.

Coating

Primer with top coat, alkyd resin Silac, total layer thickness min. 180μm,

Standard colour: Pure white (RAL9010)

Options

Multi-purpose door, control niche, connector mounting plates, guide rails, stud walls, noise protection screen, 180° deflection, fan connection

Kontakt

Korfmann Lufttechnik GmbH

Postfach 1749

58407 Witten

+49 2302 1702-0

+49 2302 1702-153

info@korfmann.com